Armstrong International provides leading-edge design, manufacturing and application of humidification and conditioned steam equipment for satisfied companies of all sizes, all over the world.

Whatever your industry, Armstrong has the energy-efficient, cost-effective solutions you need to achieve trouble-free control of your humidity. Our products are engineered to consistently deliver the clean, reliable, precisely controlled humidification necessary for reducing static discharge and achieving a pleasant, comfortable environment.

Armstrong Humidification Solutions Catalog

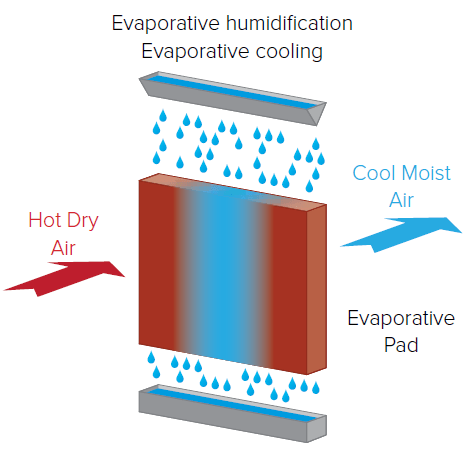

Evaporative Pad Adiabatic Humidifier Cooler—EvaPack™ Series

Armstrong’s EvaPack™ is a unique, evaporative pad humidifier cooler that utilizes free cooling while delivering best-in-class efficiency, with the lowest pressure drop and largest contact surface on the market. EvaPack™ efficiently converts ordinary, liquid, tap water to water vapor using the simple, natural, efficient process of evaporation. Dry air passes through a corrugated bank of wetted cells media made from nonorganic wet fibers. EvaPack™ cools and humidifies the air using sensible air heat to evaporate the water, which consumes less energy and minimizes pressure drop.

Learn More About EvaPack™ Adiabatic Humidification and Cooling for Data Centers

Only EvaPack™ offers a no-glue construction that allows it to be compatible with all water types and can extend its lifespan up to 7 years. EvaPack™ has the noncombustible Euro Class A1 fire rating as well as the worlds strictest international hygienic certification, VDI6022.

Conditioned Steam

Armstrong’s innovations in steam humidification are fundamentally unique because they begin with the steam, not the humidifier. Unlike units that simply disperse steam, Armstrong’s direct-steam humidifiers work with the steam, guiding it through a carefully engineered, four-step conditioning process developed by our experts.

Armstrong’s Four-Step Steam Conditioning Process

- Slow and Strain—Steam is slowed down and strained to remove particulate matter.

- Separate—Condensate is separated from the steam.

- Dry—Steam enters a drying chamber; any remaining mist is re-evaporated.

- Silence—The drying chamber is filled with stainless steel silencing material that absorbs the noise of escaping steam as it is generated at the control valve.

Armstrong offers:

Cast Iron Conditioned Steam Humidifiers

Stainless Steel Direct Steam Humidifiers

Steam Shower Humidifiers

Humidifier Operators

Steam-to-Steam Humidifiers

HumidiPack® Steam Dispersion Panels

Control Valves

Unfired Steam Generators

Atomization Humidifiers

Armstrong’s atomization humidifiers deliver energy-efficient operation by reducing cooling load and water waste, as well s maintenance costs, while improving reliability over many other evaporative systems. Armstrong’s PressureFog™ and Cool-Fog® are high-quality industrial-grade atomizing humidification solutions that are suitable for a wide variety of environments and applications.

Electric Steam Humidifiers

Electric steam humidifiers are used when a source of steam is not available. Armstrong offers a variety of electrode, ionic bed and heater type electric steam humidifiers.

Gas-Fired Steam HumidiClean™

Armstrong’s Gas-Fired HumidiClean™ operates economically on natural gas or propane. The Ionic Bed Technology reduces costs of labor and downtime associated with cleaning humidifiers. HumidiClean™ is adaptable to various water qualities, and service life cycle and tank drainage are field-adjustable. CSA-certified and CGA-approved.

Ionic Bed Technology

Ionic beds consist of a fibrous medium that attracts solids from the water as its temperature rises, minimizing the buildup of solids on the heat exchanger and inner tank walls. Once the ionic beds have absorbed their capacity of solids, a signal light on the humidifier tells you to change them—a mere 15-minute task.

- Reduced cleaning of the tank heat exchanger

- Reduced drain-screen cleaning—allowing for effective tank blowdown

- Reduced heat-exchanger surface temperatures, with no output reduction

- Reduced water and energy consumption due because of fewer required tank blowdowns

- No need for wasteful surface skimmers

Specialized Steam Distribution Methods

Armstrong offers a number of specialized steam distribution methods to meet the requirements of widely varying applications.

Series M/MH – Conditioned (Pressurized)/Single

The Importance of Humidity Control

Humidity exerts a powerful influence on environmental and physiological factors in any industry. Improper humidity levels (either too high or too low) can produce an uncomfortable or unsafe atmosphere, as well as costly production problems, material deterioration, or dangerous issues.

Dry air or fluctuating humidity can cause serious production problems and/or material deterioration, especially when processing or handling hygroscopic materials such as wood, paper, textile fibers, leather or chemicals. In dry atmospheric conditions, static electricity can interfere with efficient operation of production machinery, computers and other office machines, as well as aggravate issues with static-prone materials such as paper, films, computer disks and other plastics. In potentially explosive environments, dry air and its resultant static electricity can be particularly hazardous.

Designing Your Humidification System

Whether you’re designing for an industrial, institutional or totally different environment, there are many factors to consider. Armstrong is here to help with a highly trained team of representatives, software and checklists.

Humidification Design Checklist

Contact an Armstrong Representative

Humid-A-ware™ Humidification Sizing and Selection

Armstrong’s Humid-A-ware™ is designed to help you size, select and document your humidification solution for projects ranging from simple to complex, eliminating the need for time-consuming pencil and paper calculations. Your responses to a series of easy-to-understand questions about your humidification application will help the program determine: humidification load, correct humidifier model number, customized equipment and data schedule, psychrometric properties of air, non-wetting distance, and complete, printable humidification application specification. Humid-A-ware utilizes climate data from weather stations throughout North America and the world to help you create an extremely accurate sizing.

Humid-A-ware™ 4.0 is web-based software, allowing us to better serve you with regular updates. Humid-A-ware™ is conveniently located in Armstrong’s Configurator (C1). Log in today to size your next humidification solution.

I’m new to both ArmstrongInternational.com and Humid-A-ware™ v4.0.

I have ArmstrongInternational.com access but I’m new to Humid-A-ware™ v4.0.

I have both Armstronginternational.com and Humid-A-ware™ v4.0 access.