In more than 100 countries, Armstrong International’s innovative products and custom solutions are hard at work, saving time, money and energy for healthcare institutions just like yours.

As global leaders in thermal utility system management, we understand the complex issues you face every day. Our expertise encompasses the processes, systems and requirements that are vital to your ability to deliver outstanding patient care. Solving your problems and making things easier for you is the reason we’re here.

A Critical Component of a Healthy Hot Water System—the Armstrong Nanobubble Generator

This patent-pending technology was developed to remove existing scale and inhibit mineral deposit buildup, resulting in a cleaner hot water system. Proven outcomes include improved operational efficiency, reduced maintenance and a longer lifespan for equipment, as well as a smaller carbon footprint.

Equipment, Tools, Technology, Services and Expertise to Meet Your Most Difficult Challenges

Armstrong’s groundbreaking solutions, advanced technology, reliable products and complete services can be tailored to your requirements for: sterilization and autoclaves, reverse osmosis, dialysis, endoscope reprocessing, cart washing, compliance and regulations, and more.

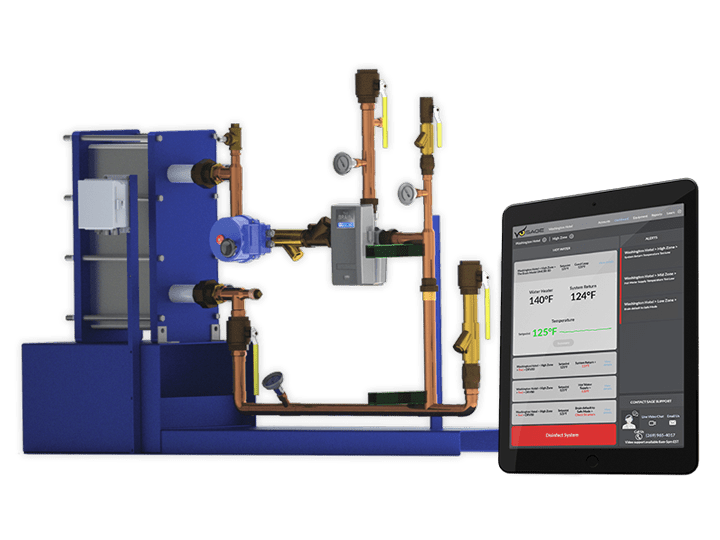

Instantaneous and Semi-Instantaneous Hot Water Generation, Digital Water Temperature Control, and Smart Utility Monitoring, Measuring and Documentation

We provide the hot water system solutions necessary to ensure compliance with Centers for Medicare and Medicaid Services (CMS) requirements and other healthcare regulations and standards of care, which are defined as acknowledged applicable laws, standards and guidelines. OSHA (1998), Joint Commission Environment of Care (2001), ASHRAE Guideline 12-2000, ASHRAE Standard 188-2015 and VA Directive 1061 (2021) are Standards of Care which include critical recommendations for establishing and monitoring hot water system temperature control limits.

State-of-the-Art Steam and Condensate System Products, Technology and Services

Armstrong’s products are engineered to consistently deliver superior accuracy and reliability as well as best-in-class quality, longevity and value—for more effective steam and condensate management. We can help you: monitor steam traps and steam dryness fraction; ensure that your steam traps are properly sized, selected and in working order; and deaerate and maintain condensate at appropriately high temperatures.

Steam and Condensate Products for Healthcare

Steam Trap Management Services Brochure

Technology and Innovation from Armstrong

Our advanced steam system efficiency methodology has United Nations and Kyoto Protocol approvals.

Armstrong’s steam system efficiency methodology, which relates to steam traps, has been approved by the United Nations Framework Convention on Climate Change (UNFCCC), and ours is the first efficiency methodology to be approved for international trading of resultant carbon dioxide (CO2) emissions under the Kyoto Protocol.

Smart Steam and Hot Water System Management Software to Help You Comply With Industry Regulations and Guidelines

SAGE® keeps you fully informed, 24 hours a day with regular updates, precise documentation, custom-filtered reports, and real-time alerts notifying you of any problems. SAGE® is a fully integrated part of your thermal utility system and engineered to work seamlessly with all of Armstrong’s real-time monitoring products.

Complete, On-Site Operation and Maintenance of Your Thermal Utilities

Our record speaks for itself. Armstrong’s O&M sites have achieved 99.9+% utility reliability, with 0 recordable instances of safety issues in 2017. Our employees adhere to OSHA 1910 and 1926 for operational and construction safety, and we comply with all applicable environmental regulations.

High-Efficiency, Low-Maintenance Adiabatic Humidification and Cooling

Armstrong’s EvaPack™ reduces energy use and delivers the lowest operating cost of any other type of humidifier—all while providing reliable, trouble-free humidity control and cooling. It is less expensive to implement and the compact design is quick and easy to install. EvaPack™ accepts any type of water and the natural evaporative process is safe and hygienic.

EvaPack™ Evaporative Pad Adiabatic Humidifier Brochure

Energy Savings and Efficiency

- Engineered to maximize efficiency and minimize pressure drop.

Example: For a 294,288.8 CFM [500 000 m3/h] airflow, a pressure drop difference of 0.2”WC [50 Pa] represents a saving of 67,500 kWh per year ($7,630.88 [6,750€]/year at $.01 [0,01€]/kWh).

- EvaPack™ uses heat present in the air for humidifying and cooling, resulting in lower energy consumption

- Optimized to provide the highest air/water contact surface—up to 12% more than traditional evaporative pads