Our custom-engineered, package solutions deliver high-efficiency heating, cooling and hot water generation.

Armstrong heat pumps provide a fundamental solution for superior thermal efficiency, de-steaming, and decarbonization by reclaiming your wasted heat and putting it to work where you need it most—as a replacement for purchased fuel. Whether your goal is cutting energy costs, reaching net zero, or both, Armstrong heat pump packages provide a comprehensive, integrated solution that will carry you into the future.

Armstrong Heat Pump Solutions Brochure

Armstrong offers significant advantages over traditional, combustion-based and electrical heating methods.

- Lower operating costs

- Less maintenance

- Increased safety

- Reduced carbon emissions

- Heating and cooling capabilities

- Proven reliability

- Longer lifespan

Our Heat Pump Packages Are a Crucial Step in Reaching Your Net-Zero Goal

Armstrong heat pumps provide a higher COP while consuming only half the electrical power of a simple electric steam boiler or hot water generator. In addition to recovering wasted heat, our heat pumps offer an efficient solution for using shallow geothermal or water from rivers, lakes, or even sewage, as a heat source. The Armstrong heat pump is an essential component in Circular Thermal℠, the heart of Armstrong’s Decarbonization Methodology.

Armstrong Heat Pumps Are at the Heart of Thermal Decarbonization

Armstrong heat pumps allow reuse of low-temperature heat (< 60°C [140°F]) that is rejected by process and cooling systems and currently wasted in most industrial plants. Through the refrigeration cycle of the heat pump, hot water temperature is increased at relatively high levels—up to 120°C (248°F). Using waste heat in the production of hot water for high-temperature cleaning or process applications replaces steam or hot water currently generated by burning fossil fuels, which can significantly reduce primary energy use by light industry facilities.

Our Heat Pumps are an economical way to generate thermal heat when efficiency (COP) exceeds the price ratio of renewable electricity to fossil fuel.

Consuming fossil fuel will no longer be an option for companies willing to decarbonize thermal generation, so recovering their waste heat becomes a must. Compared to other renewable alternatives, the impact of Armstrong heat pumps (fueled by renewable electricity) on reducing CO2 emissions makes tackling the thermal decarbonization challenge easier and more economical.

No time to waste.

The recovery of low-grade waste heat will be one of the most significant contributors to energy efficiency, thus facilitating the thermal decarbonization challenge the world is facing. Armstrong heat pump packages are the solution for significantly decreasing the primary energy consumption of plants. Thermal decarbonization is achievable—safely, reliably, and economically.

Institutional

Electroplating

Dryer Heat Recovery, Chiller and Pool Heating

Outdoor Installation

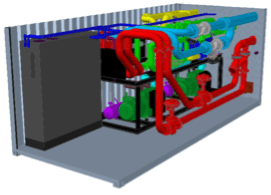

Container Solution

Hydraulic Extension

Tailor-Made for Your Industry and Requirements

Your Armstrong heat pump will be an integrated, package solution that’s built for your specific project and application. We understand that every facility is different, so Armstrong’s specialists will conduct the engineering studies necessary to determine the best configuration to address your unique needs.

The result will be a complete, integrated package that may include heat pump, secondary water heater, mixing station with digital recirculating valve, buffer tank, flow and BTU meters, COP monitoring system, recirculation pump skid, secondary heat exchanger skid, heat pump housing, power and control panel, and more.

Higher Than 100% Efficiency

In a steam or electrical heating system, the amount of heat produced is a portion of the energy consumed to produce it, so efficiency is less than 100%. The Armstrong heat pump extracts wasted heat from a heat source (chilled water / cooling tower water / any consistent waste heat) and raises the temperature to a useful level. Because the amount of heat produced is not dependent on the amount of energy consumed, efficiency can surpass 100%.

Industry Applications

- Brewery and Malt House—Wort preparation, drum and bottle cleaning, malt drying

- Dairy—Container sterilization

- Sugar Production—Boiling process for making syrups, thickening

- Food Manufacturing—Boiling processes, grain and fodder drying

- Institutions—Hot and chilled water for hotels, hospitals, schools and universities

- Paper Production—Pulp drying

- Processing Technology—Reclaiming of cleaning solutions

- Pharmaceutical—Hot water and chilled water for air handling units, process heating and cooling

Features and Benefits

Custom Engineering

- Tailor-made heat pumps, heat recovery chillers, special applications

- Special heat exchanger materials for various mediums

- Position and execution of connections according to customer requirements

- CAD construction and CFD simulation

- Adapted design for replacement or special insertion

A Full Range of Accessories

- Additional equipment, such as pumps, valves, sensors, buffer vessels

- Integrated on the machine or supplied separately

- Adaption of frame size to accommodate special conditions

- Sound-isolating and weather-proofed housing

- Container installation or truck-mounted aggregates

Precision Electrical Design

- Electrical cabinet attuned to all components and accessories

- Control by Programmable Logic Controller (PLC)

- Data input and output via touch panel

- Extensive visualization of refrigeration circuit and periphery

- All common communication protocols like Modbus, Profibus, Profinet and BACNet